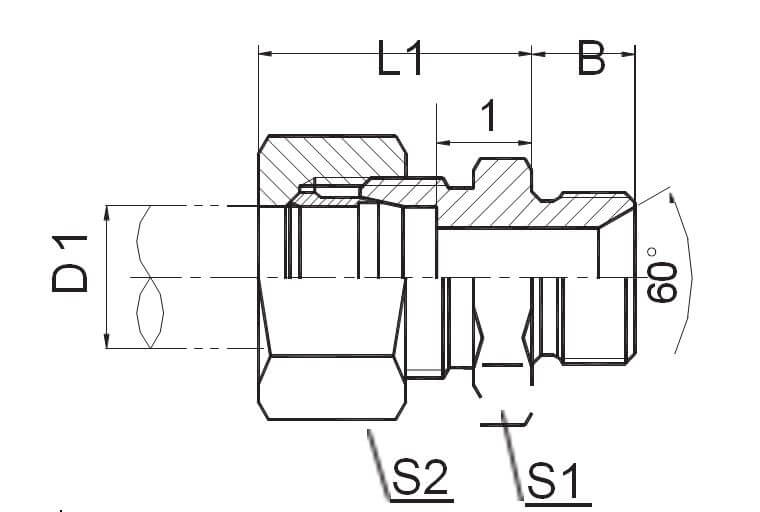

1. I-BSP Thread 60° Cone Sealing noma I-Bonded Seal Stud Ends, ilungele ukudluliswa kwe-hydraulic hose.

2. Yenziwe ngensimbi ye-Medium Carbon eqinile ukuze isebenze isikhathi eside.

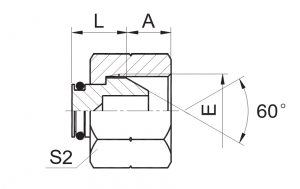

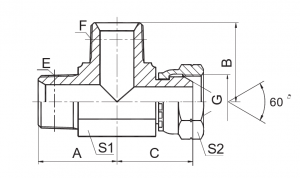

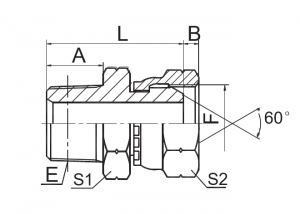

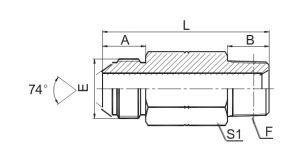

3. Ifaka ukuxhumana kowesilisa kanye nohlobo lwekhanda leHexagon ukuze kufakwe kalula.

4. Itholakala ngombala Osagolide/Isiliva ne-Zinc Plated surface ukumelana nokugqwala.

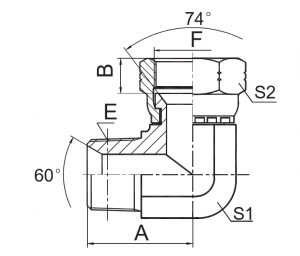

5. Izinketho eziguquguqukayo ezinezinhlobo eziqondile / ze-Tee / Cross kanye nezimo eziqondile / zendololwane.

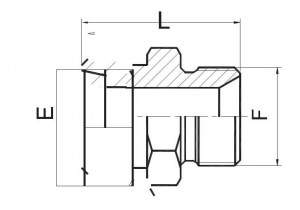

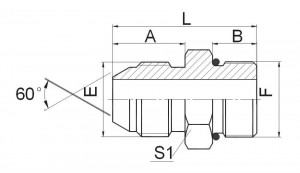

| INGXENYE NO. | E | F | D1 | B | LI | L1 | L | S1 | S2 | I-MPa |

| I-S1DB- 14-04 | I-M14X1.5 | I-G1/4″X19 | 6 | 12 | 13 | 28 | 30 | 19 | 17 | 63 S |

| I-S1DB- 16-04 | I-M16X1.5 | I-G1/4″X19 | 8 | 12 | 13 | 28 | 32 | 19 | 19 | |

| I-S1DB- 16-06 | I-M16X1.5 | I-G3/8″X19 | 8 | 13.5 | 15 | 30 | 33.5 | 22 | 19 | |

| I-S1DB- 18-04 | I-M18X1.5 | I-G1/4″X19 | 10 | 12 | 12.5 | 29 | 32 | 19 | 22 | |

| S1DB- 18-06 | I-M18X1.5 | I-G3/8″X19 | 10 | 13.5 | 14.5 | 31 | 33.5 | 22 | 22 | |

| I-S1DB- 18-08 | I-M18X1.5 | I-G1/2″X14 | 10 | 16 | 14.5 | 31 | 36 | 27 | 22 | |

| I-S1DB-20-04 | I-M20X1.5 | I-G1/4″X19 | 12 | 12 | 14.5 | 31 | 34 | 22 | 24 | |

| I-S1DB-20-06 | I-M20X1.5 | I-G3/8″X19 | 12 | 13.5 | 14.5 | 31 | 35.5 | 22 | 24 | |

| I-S1DB-20-08 | I-M20X1.5 | I-G1/2″X14 | 12 | 16 | 14.5 | 31 | 38 | 27 | 24 | |

| I-S1DB-22-08 | I-M22X1.5 | I-G1/2″X14 | 14 | 16 | 16 | 34 | 40 | 27 | 27 | |

| I-S1DB-24-06 | I-M24X1.5 | I-G3/8″X19 | 16 | 13.5 | 15.5 | 34 | 37.5 | 27 | 30 | 40 S |

| I-S1DB-24-08 | I-M24X1.5 | I-G1/2″X14 | 16 | 16 | 15.5 | 34 | 40 | 27 | 30 | |

| I-S1DB-24-12 | I-M24X1.5 | I-G3/4″X14 | 16 | 18.5 | 17.5 | 36 | 44.5 | 32 | 30 | |

| I-S1DB-30-12 | I-M30X2 | I-G3/4″X14 | 20 | 18.5 | 17.5 | 39 | 48.5 | 32 | 36 | |

| I-S1DB-30-08 | I-M30X2 | I-G1/2″X14 | 20 | 16 | 17.5 | 44 | 32 | 36 | ||

| I-S1DB-36-08 | M36X2 | I-G1/2″X14 | 25 | 16 | 19 | 43 | 48 | 38 | 46 | |

| I-S1DB-36-12 | M36X2 | I-G3/4″X14 | 25 | 18.5 | 19 | 43 | 50.5 | 38 | 46 | |

| I-S1DB-36-16 | M36X2 | G1″X11 | 25 | 20.5 | 20 | 44 | 52.5 | 41 | 46 | |

| I-S1DB-42-20 | I-M42X2 | G1 .1/4″X11 | 30 | 20.5 | 21.5 | 48 | 54.5 | 50 | 50 | |

| I-S1DB-52-24 | M52X2 | G1 .1/2″X11 | 38 | 23 | 23 | 54 | 62 | 55 | 60 | 31.5 |

I-BSP Thread 60° Cone Sealing noma I-Bonded Seal Stud Ends, isixazululo esifanelekile sezinhlelo zokusebenza zokudlulisa ipayipi le-hydraulic.Iklanywe ngokunemba nokunaka imininingwane, iziphetho zethu ze-stud ziqinisekisa ukuxhumana okuthembekile nokungavuzi kwesistimu yakho ye-hydraulic.

Kwenziwe kusetshenziswa izinto zekhwalithi ephezulu, njenge-Steel & Zinc Plated, Brass, noma iStainless Steel, iziphetho zethu ze-studi ziklanyelwe ukuqina nokuphila isikhathi eside.Ukusetshenziswa kwe-Medium Carbon Steel kuqinisekisa ukusebenza okuqinile, okubavumela ukuthi bamelane nezidingo zokusetshenziswa kwe-hydraulic.

I-BSP yethu ye-BSP Thread 60 ° Cone Sealing noma i-Bonded Seal Stud Ends ifaka ukuxhumana kowesilisa, okuqinisekisa ukuhambisana nezinhlelo eziningi ze-hydraulic.Uhlobo lwekhanda leHexagon lwenza kube lula ukufakwa, lukongela isikhathi nomzamo ngesikhathi sokuhlanganisa.

Ngokumelana nokugqwala njengokubalulekile, iziphetho zethu ze-stud zitholakala ngezinketho zemibala yeGolden/Silver futhi ziyiZinc Plated.Lokhu kwelashwa okungaphezulu kunikeza isivikelo esihle kakhulu ekonakalini, kunweba ubude besikhathi sezinto zokufakwa kanye nokugcina ukusebenza kwazo ngisho nasezimweni ezinzima.

Ukuze kuhlangatshezwane nezidingo ezihlukene zohlelo lokusebenza, sinikeza izinketho eziguquguqukayo ezinezinhlobo eziqondile/Izinwele/Iziphambano kanye nezimo eziqondile/indololwane.Lokhu kukuvumela ukuthi ukhethe iziphetho ze-stud ezifanela kangcono ukucushwa kwesistimu yakho ye-hydraulic, uqinisekise ukulingana okunembayo nokusebenza okuphelele.

Kwa-Sannke, sibeka phambili ikhwalithi nokunemba.I-BSP yethu ye-Thread 60° Cone Sealing noma i-Bonded Seal Stud Ends ihlolwa ngokucophelela ukuze kuqinisekiswe ukuthi imicu nobukhulu buhlangabezana nezindinganiso eziqinile.Ukwengeza, sisusa ama-burrs ukuze siqinisekise ukusebenza okushelelayo nokungenamthungo.Kunikezwa izitifiketi zezinto ezibonakalayo, okuqinisekisa ubuqotho bemikhiqizo yethu.

Khetha i-Sannke, ifekthri engcono kakhulu yokufaka umshini wokudonsa amanzi, ukuze uhlangabezane nezidingo zakho zokufakwa kwamanzi.Xhumana nathi namuhla ukuze uhlole uhla lwethu olubanzi lokufakwa kwe-hydraulic futhi uzwe ukuzibophezela kwethu ekwenzeni okuhle nokwaneliseka kwamakhasimende.

-

I-JIS GAS Male / SAE Male O-Ring |I-Cr6+ yamahhala yeZin ...

-

I-BSP Lock Nut |Ikhwalithi ephezulu, iqinile futhi iqinile...

-

I-BSPT Owesilisa / BSPT Owesilisa / BSP Owesifazane 60° I-Cone Ada...

-

BSPT Owesilisa / BSP Owesifazane 60° Ukufakwa Kwekhoni |Vers...

-

I-JIC Male 74° Cone / NPT Indoda Ende Ngokwengeziwe |Ibala...

-

90° NPT Male / JIC Female 74° Seat Adapter |Du...