Ukufakwa kwe-Hydraulic hose yizici ezibalulekile ezixhuma izingxenye ezihlukahlukene ze-hydraulic, okuvumela ukudluliswa kwamandla oketshezi ngaphakathi kwesistimu ye-hydraulic.Lokhu kufakwa kubalulekile ekugcineni amasistimu asebenza ngogesi athembekile futhi asebenza ngempumelelo.Kodwa-ke, ukukhomba uhlobo olufanele lokufakwa kwepayipi le-hydraulic kungaba inselele, uma kucatshangelwa izinhlobonhlobo zokufakwayo ezitholakala emakethe.Ukufakwa kwe-Hydraulic hose kunamathela ku-ISO 12151 standard.

Kulesi sihloko, sizophenya ngokubaluleka kokuhlonza ukufakwa kwepayipi le-hydraulic futhi sinikeze umhlahlandlela wesinyathelo ngesinyathelo ukukusiza ukuthi uzulazule le nqubo ngempumelelo.

Ukubaluleka Kokuhlonza Ukufakwa Kwe-Hydraulic Hose

Ukuhlonza okulungile kweukufakwa kwe-hydraulic hoseibalulekile ngenxa yezizathu eziningana.Okokuqala, ukusebenzisa ukufaka okungalungile kungaholela ekuvuzeni, ekwehleni kwengcindezi, ngisho nokwehluleka kohlelo.Okwesibili, inqubo yokuhlonza ikuvumela ukuthi ukhethe ukufaka esikhundleni esifanele uma kudingeka, ukonga isikhathi nezinsiza.

Izinhlobo zeHydraulic Hose Fittings

I-DIN Hydraulic Fittings

Ukufakwa kwe-DIN ye-hydrauliczenzelwe ukuhlangabezana namazinga aphezulu kakhulu ekhwalithi nokusebenza ezinhlelweni ezisebenza ngamanzi.Lolu hlobo lokufakwayo lusekelwe esimisweni sokuklama sokufakwa se-24 ° Metric Fittings, esicaciswe ku-ISO 12151-2.Leli zinga liqinisekisa ukuhambisana nokunye ukufakwa ezinhlelweni zamanzi, okuvumela ukufakwa nokusetshenziswa okungenamthungo.

Ukufakwa kweFlange

Ukufakwa kwe-Flangezenzelwe ukuhlangabezana futhi zedlule izindinganiso zemboni zokwethembeka nokusebenza.Amazinga wokuklama wokufaka acaciswe ku-ISO 12151-3, eqinisekisa ukuhambisana nokunye ukufakwa ezinhlelweni zamanzi.Elinye izinga elihlanganisiwe yi-ISO 6162.

I-ORFS Hydraulic Fittings

I-ORFS hydraulic fittingszenzelwe ukuhlangabezana futhi zedlule izindinganiso zemboni zokwethembeka nokusebenza.Idizayini yokufaka yalokhu kufakwa ithobela izinga le-ISO 12151-1, eliqinisekisa ukuhambisana nokunye ukufakwa ezinhlelweni zamanzi.Izinga le-ISO 8434-3 liphinde lahlanganiswa ukuze kuthuthukiswe ukusebenza kwalolu hlobo lokulinganisa.

I-BSP Hydraulic Fittings

Izindinganiso eziphakeme kakhulu zezimboni zekhwalithi nokwethembeka, njengoba kushiwo ku-ISO 12151-6, kuhlangatshezwana nazoI-BSP hydraulic fittings.I-ISO 8434-6 nayo yahlanganiswa ukuze kuthuthukiswe ukusebenza kwe-BSP hydraulic fittings nakakhulu.

I-SAE Hydraulic Fittings

Ngezicelo ezahlukahlukene,Ukufakwa kwe-SAE hydraulichlinzeka ngesixazululo esinokwethenjelwa nesisebenzayo.Zenzelwe ukuhlangabezana nezidingo eziphakeme kakhulu zemboni, ukuhlanganisa inqubo yokuklama yokufaka ye-ISO 12151 namazinga wokuklama we-ISO 8434.

I-JIC Hydraulic Fittings

I-JIC hydraulic fittingszenzelwe ukuthi zifakwe kalula nangempumelelo njengoba zihambisana nezinga le-ISO 12151-5 lokuklama.Izinga lokuklama le-ISO 8434-2 lihlanganiswe nalokhu kufakwa ukuze kuqinisekiswe ukuthi kugcwalisa ikhwalithi ephezulu kakhulu nemibandela yokuphepha.

Isinyathelo Ngesinyathelo Umhlahlandlela Wokuhlonza Ukufakwa Kwe-Hydraulic Hose

1. Qoqa Amathuluzi Adingekayo

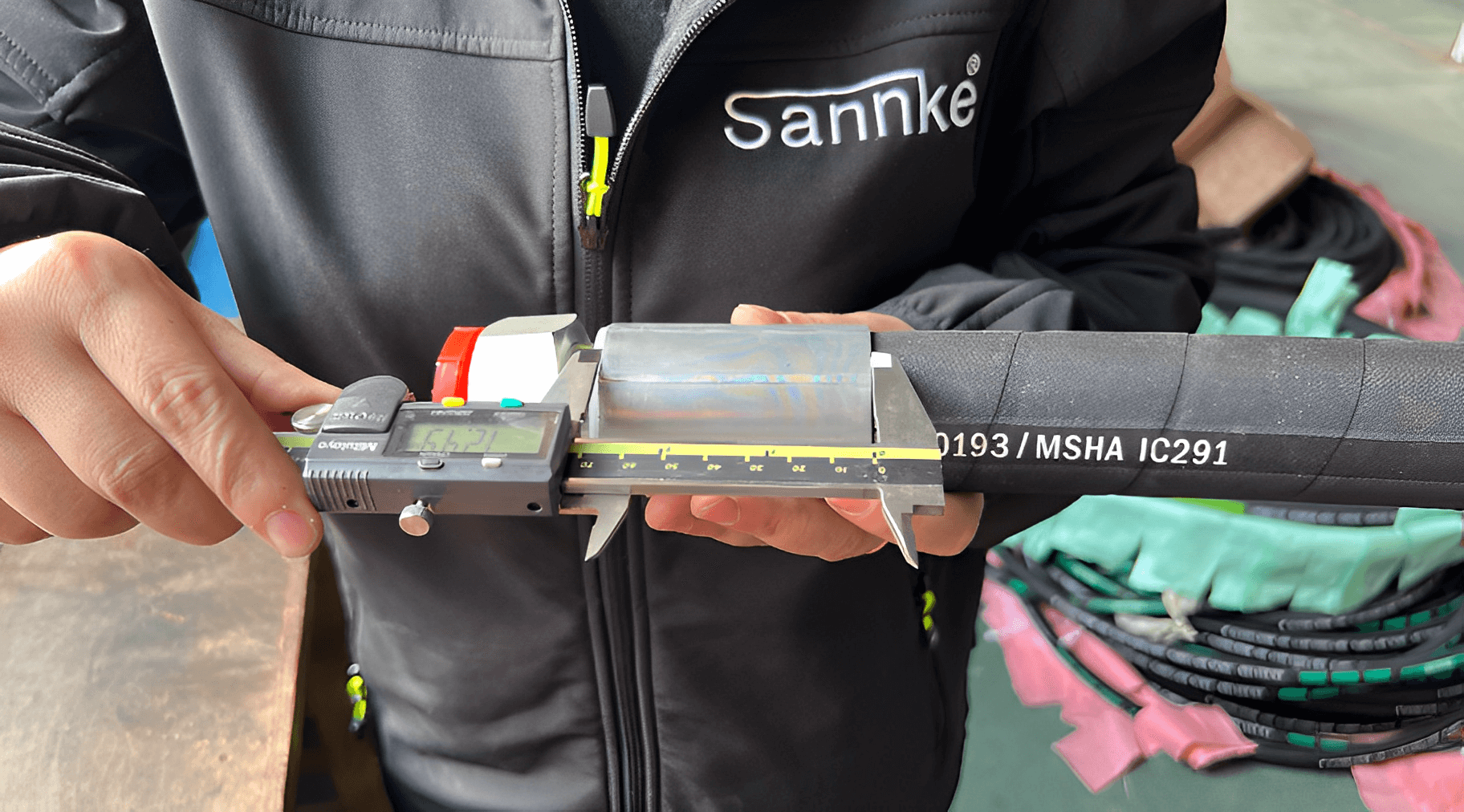

Ngaphambi kokuthi uqale inqubo yokuhlonza, qoqa amathuluzi adingekayo, okuhlanganisa i-caliper, i- thread gauge, irula, kanye ne- thread pitch gauge.

2. Kala Usayizi Womucu kanye Nephimbo

Sebenzisa i-gauge yentambo kanye ne-caliper ukukala usayizi wentambo kanye ne-pitch ngokunembile.

3. Hlola Ukuma Kwe-Flange Nosayizi

Hlola ukuma kwe-flange bese ukala usayizi wayo ukuze uthole ukuthi ifanele yini.

4. Hlola Indlela Yokunqamula Ngokushesha

Hlola idizayini nosayizi wokunqanyulwa okusheshayo kokufakwayo ukuze uthole ukuhlonza okufanele.

5. Hlola Isitayela seCrimp kanye Nobubanzi

Hlola isitayela se-crimp futhi ulinganise ububanzi ukuze uhlonze ukufaka kahle.

6. Linganisa Uhlobo Lokuminyanisa kanye Nokufaneleka

Khomba uhlobo lokuminyanisa nezicaciso ezifanele zokuhambisana.

Amaphutha Avamile Okufanele Ugwenywe Lapho Uhlonza Ukufakwa Kwe-Hydraulic Hose

Ukuziba Izinyathelo Zokuphepha

Ngaso sonke isikhathi beka phambili ukuphepha lapho usebenza namasistimu asebenza ngamanzi.Gqoka izinto zokuzivikela ezifanele futhi ucindezele isistimu ngaphambi kokuzama noma yikuphi ukuhlonza noma ukushintshwa.

Ukungazi Ukucaciswa Kwe-Hose

Ukuqonda ukucaciswa kwepayipi, okufana nokokusebenza kwayo, usayizi, kanye nesilinganiso sokucindezela, kubalulekile ekuhlonzeni ukulingana okulungile.

Ukweqa Umehluko we-Thread Pitch

I-Thread pitch idlala indima ebalulekile ekusebenzisaneni okufanelekile.Ukweqa ukuhluka kwephimbo lentambo kungaholela ekuvuzeni nasekuxhumekeni okungalungile.

Ukubaluleka Kokuhlonza Ngokufanelekile Ukufakwa Kwe-Hydraulic Hose

Ukuqinisekisa Ukuphepha Nokwethenjelwa

Ukuhlonzwa okufanele kokufakwayo kuqinisekisa ukuthi isistimu ye-hydraulic isebenza ngokuphepha nangokwethembeka, kunciphisa ubungozi bezingozi nokulimala kwemishini.

Ukuvimbela Isikhathi Sokuphumula Esibizayo

Ngokufaka izinto ezifanele esandleni futhi ushintshe ngokushesha ezilimele, unganqanda isikhathi sokuphumula esibizayo futhi ugcine ukukhiqiza.

Ukuthuthukisa Ukusebenza Kwesistimu Ye-Hydraulic

Ukusebenzisa ukufakwa okufanele kuthuthukisa ukusebenza kwesistimu ye-hydraulic, kukhuphule ukusebenza kahle nokunciphisa ukumosheka kwamandla.

Amathiphu Okugcina Nokushintsha Ukufakwa Kwe-Hydraulic Hose

Ukuhlola Okuvamile

Hlola njalo ukufakwa kwe-hydraulic ukuze uthole izimpawu zokuguga, ukugqwala, noma ukulimala.Shintsha izinto ezigugile ngokushesha.

Amasu Okufaka Afanele

Qinisekisa ukuthi okokufaka kufakwe kahle ngokulandela imihlahlandlela yomkhiqizi nokusebenzisa amathuluzi afanelekile.

Ukushintsha Okokufaka Okulimele

Lapho ushintsha ukufakwa kwe-hydraulic, khetha uhlobo olufanele lokulinganisa nosayizi ukuze ugcine ubuqotho besistimu.

Imibuzo Evame Ukubuzwa

Q: Ingabe kuyadingeka ukugqoka izinto zokuzivikela lapho uhlonza okokufakwa kwe-hydraulic hose?

IMPENDULO: Yebo, ukugqoka okokuvikela kubalulekile ukuvikela ukulimala ngenkathi usebenza ngamasistimu asebenza ngamanzi.

Umbuzo: Ngingasebenzisa noma yikuphi ukulinganisa uma ngingenasiqiniseko ngokuhlonza ngokuqondile?

IMP: Ukusebenzisa ukufaka okungalungile kungaholela ekuhlulekeni kwesistimu futhi akunconyiwe.Ngaso sonke isikhathi qiniseka ukuthi ukuhlonza ukufaka kahle ngaphambi kokufaka.

Q: Kufanele ngihlole kangaki ukufakwa kwe-hydraulic?

A: Ukuhlola okuvamile kubalulekile;kunconywa ukuthi uhlole ukufakwa ngesikhathi sokuhlolwa kokulungisa okujwayelekile.

Q: Yini okufanele ngiyenze uma ngithola i-hydraulic fitting eyonakele?

IMP: Uma uthola okokufaka okonakele, kushintshe ngokushesha ufake uhlobo olulungile nosayizi ukuze ugcine ubuqotho besistimu.

Q: Ingabe okokufakwa kwe-crimp kungasetshenziswa kabusha?

IMPENDULO: Ukufakwa kwe-crimp akuklanyelwe ukusetshenziswa futhi, futhi ukuzama ukwenza kanjalo kungase kuphazamise ukusebenza nokuphepha kwazo.Njalo sebenzisa okokufaka okusha lapho ushintsha amadala.

Isiphetho

Noma ubani osebenzelana nezinhlelo zokudonsa amanzi kufanele abe nokuqonda okuyisisekelo kokuthi kutholwa kanjani ukufakwa kwepayipi le-hydraulic.Iqinisekisa ukuphepha kwesistimu, ukusebenza kahle, nokusebenza.Ngokulandela umhlahlandlela wethu wesinyathelo nesinyathelo futhi uqonde izinhlobo ezahlukene zokufakwa, ungakwazi ukubhekana ngokuzethemba nanoma yimuphi umsebenzi wokuhlonza i-hydraulic fittting.

Isikhathi sokuthumela: Aug-07-2023